Spinder supply a range of Buschmann manure mixers that meet the most stringent operational requirements.

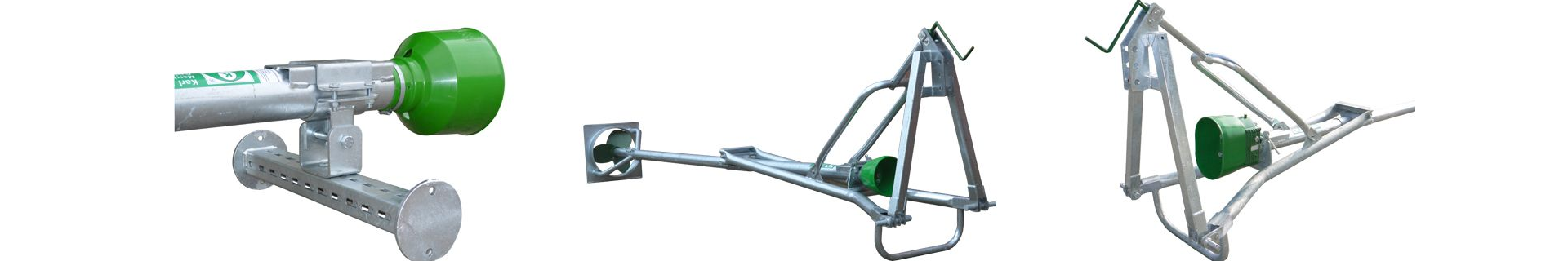

A manure mixer has bearings on the PTO side, in the middle and a bearing at the mixer auger.

Models E1-102 and L-E1 are fitted in many places with maintenance-free groove ball bearings with a 2RS sealing. The maximum speed is 1000 revolutions per minute.

Model C/E1-102 is fitted with a maintenance-free groove ball bearing on the PTO side, sleeve bearings as centre bearings and a sleeve bearing near the mixer auger. The maximum speed is 540 revolutions per minute.

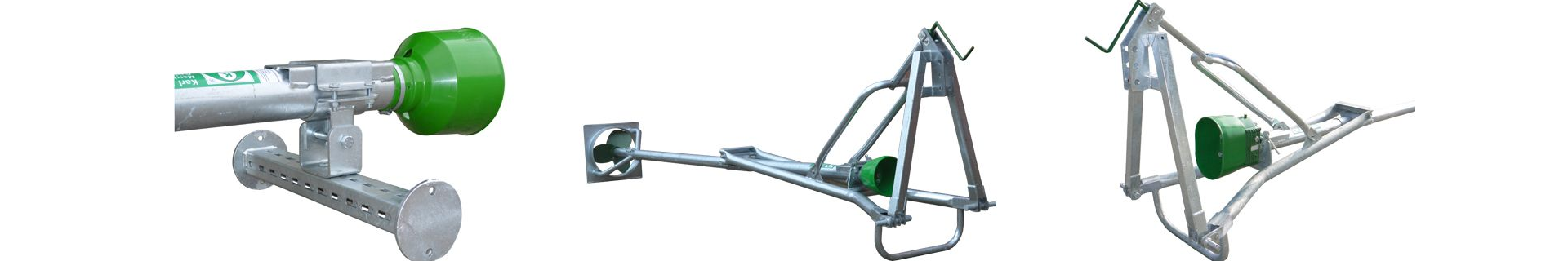

For a mixer in a pit to work properly, a built-in mixer frame (70 x 70 cm) must be part of an intermediate wall. Using a guide rail, the mixer can be conveniently put in place. Standard guide rails are 5 metres long. 3-metre-long guide rails are also available.

The guide rails can be suspended from a suspension bracket.

It is also possible to go for a manure mixer with no 3-point trestle, in which case the mixer must be attached in the mixer pit by means of an adjustable holder. The standard adjustable holder has a setting range of 60 to 120 cm. A reinforced version has a setting range of 100 to 170 cm.

A manure mixer with no 3-point trestle can still be used with the accessory support trestle with a guide rail.

In practice, a reverse gearbox is used if the pit is not 'released'. Especially when the manure pit is almost filled up, it may happen that a sucking mixer spills the manure over the edge. Running the mixer for a short period of time will make the manure move faster and better.

When a reverse gearbox is frequently used, we recommend a model E1/102 mixer.

Please note! When using the reverse function:

All information about the Tractor-driven manure mixers can be found here:

Would you like to receive information about PTO-driven mixer? We will be happy to tell you what we can do. Fill in your details here, and we will contact you.

Spinder works exclusively with dealers who share the same core values: quality, reliability and professionalism. There is always a dealer in your region.